Optimizing Flame Retardant Coating on PET Substrates

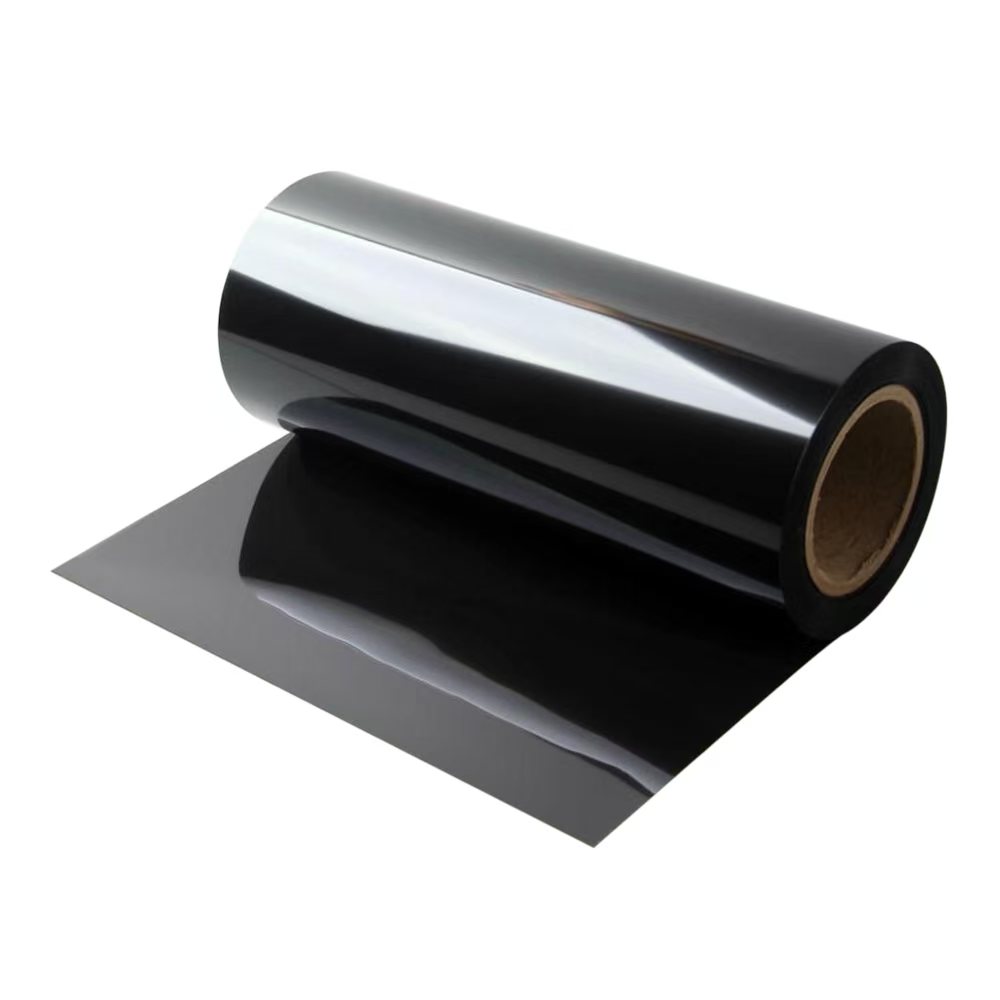

PET films are widely used in electronics, labels, packaging, and industrial insulation. Many of these applications require the films to meet fire safety standards, which is often achieved by applying flame retardant coatings. Selecting the right PET flame retardant for coating is a critical part of the production process. This article explains how to match flame retardants with coating systems and ensure flame retardant process compatibility across manufacturing lines.

1. Why Use Coatings Instead of Bulk Additives?

While some PET applications involve integrating flame retardants directly into the polymer during extrusion (PET extrusion with flame retardant), coatings offer several advantages:

- Maintain PET’s native transparency and physical properties

- Apply functionality only to specific surfaces

- Enable retrofit on existing non-FR PET films

- Offer tunable thickness and multi-layer options

This makes coatings ideal for sensitive or high-value applications like electronics and medical packaging.

2. Criteria for Selecting PET Flame Retardant for Coating

Choosing the right PET flame retardant for coating involves evaluating several factors:

- Chemical compatibility: Will the flame retardant disperse well in the chosen binder (e.g., acrylic, polyurethane, silicone)?

- Thermal stability: Can the coating be dried at standard PET processing temperatures (~100–150°C) without decomposition?

- Adhesion: Will the coating properly anchor to the PET surface, or does surface pretreatment (e.g., corona/plasma) need to be applied?

- Optical requirements: Some applications require high clarity or color neutrality.

- Regulatory compliance: Must meet UL94, RoHS, or REACH standards.

3. Common Types of Coatable Flame Retardants

Flame retardants used in coatings include:

- Intumescent systems: Expand when heated, forming a char barrier

- Phosphorus-based additives: Offer low-smoke, halogen-free protection

- Melamine derivatives: Provide nitrogen-based flame inhibition

- Nano-fillers: Enhance char formation and mechanical durability

These options must be optimized for melt processing PET flame retardants if the coating is part of a coextrusion system or inline lamination.

4. Process Compatibility and Application Techniques

Ensuring flame retardant process compatibility means the coating must work with existing line parameters, including:

- Viscosity for slot-die, gravure, or spray coating

- Drying time and temperature profile

- Crosslinking or curing method (UV, thermal, or chemical)

- Rewinding and slitting behavior post-coating

Incompatibilities can cause delamination, blistering, or haze. Always conduct pilot trials before large-scale production.

5. Case Example: Flame Retardant Label Film

A manufacturer needed to convert a clear PET label stock into a flame-retardant version for use on lithium battery packs. Requirements included:

- UL94 VTM-0 flammability rating

- Minimal haze

- UV-cured coating compatibility

- RoHS compliance

The solution involved a phosphorus-nitrogen synergistic flame retardant in a UV-curable acrylic binder. After surface treatment, the coating achieved excellent adhesion and transparency while passing vertical burn tests—showcasing a successful example of PET flame retardant for coating.

Conclusion

Flame retardant coatings on PET substrates enable manufacturers to meet fire safety standards without compromising film performance or production efficiency. By focusing on chemical compatibility, process stability, and performance goals, producers can achieve excellent flame retardant process compatibility and meet regulatory demands using reliable melt processing PET flame retardants.

Tags:

- PET flame retardant for coating

- flame retardant process compatibility

- melt processing PET flame retardants

- PET extrusion with flame retardant

READ MORE:

Telephone: 008613530419893

E-mail:marie@selfadhesivefilm.com

ADDRESS (Shenzhen):903-286, Building A2, Guangming Technology Park, China Merchants Group, Guanguang Road, Fenghuang Community, Fenghuang Street, Guangming District, Shenzhen, Guangdong.

ADDRESS (Dongguan): 3rd Building No.45 Yinhu Road Shishuikou Community,Qiaotou Town, Dongguan, Guangdong.